Extraction process :

The cultivation of Iris must be done on a well-drained rocky soil and requires a great sun exposure. The plant is grown for three years before its rhizome is harvested in January and February or July and August.

Today, iris harvesting is increasingly mechanized, allowing the rhizomes to be removed easily from the ground. After harvesting, iris rhizomes are trimmed and washed.

There are then several types of process before putting the rhizomes to dry. In some (rare) regions of the world such as Tuscany or a little in Morocco, the rhizomes are peeled and cleaned after harvesting (this is called ''white '' iris). This process is complex because it cannot be mechanized and must be done by hand. It does, however, result in a much better olfactory quality. The huge majority of global production does not undergo this process and is ''simply '' sliced mechanically (known as ''black '' iris).

Whatever the process, they are then left to dry in the sun for several days. At this stage, the rhizomes are still almost odorless. This drying is essential because it determines the degree of maturation of the rhizomes, an important factor in the rate of transformation of irone, itself a factor in the olfactory quality of the butter or Iris absolute.

Three more years of drying then follow, during which the rhizome synthesizes molecules called irones, chemically close to ionones. This step is crucial to obtain the olfactory quality of the root.

(A bacterial treatment can accelerate the maturation of the roots from three years to just a few days! However, the treatment has a negative impact on the olfactory quality of the root).

Rhizomes are then powdered and undergo molecular hydrodistillation (under 0.5 to 1.5 bar pressure and for about 15 hours), to obtain a Iris Butter (concrete) with a yield of about 0.2%. This butter can then undergo fractional distillation to obtain Iris Absolute with a yield of about 0.04% from the rhizomes. Iris powder can also be treated directly with volatile solvents to obtain Iris Resinoid with a yield of about 3 to 4%. These yields as well as the time required for production explain the cost of this raw material.

In terms of production, the concrete that is preferred, about 200kg are produced each year, containing about 10-20% irone, sold at approx. 10k€/Kg. Only a few kilos of Absolute d'Iris are produced, containing more than 60% irone, sold at approx. 50k€/Kg. Resinoid is not much produced.

Chemotypes :

In perfumery, there are 2 main species of Iris:

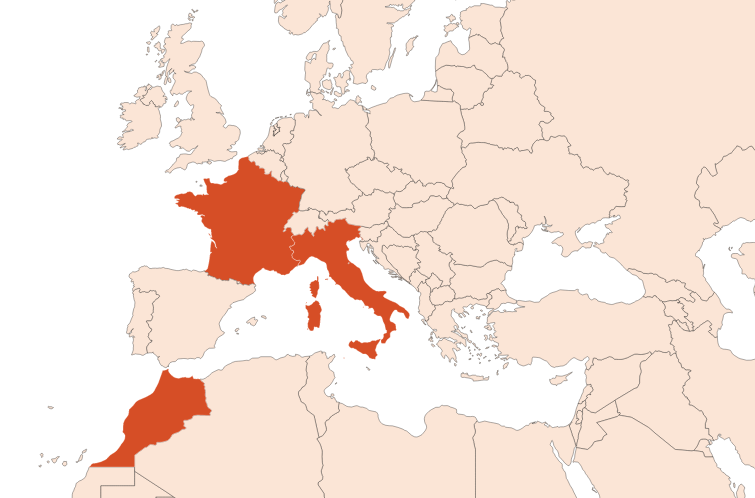

Iris pallida, grown in Italy (Tuscany) primarily rich in cis-γ-irone, then cis-α-irone.

Iris germanica including the emblematic variety Iris germanica var. florentina (originally from Italy too), now cultivated in China, Morocco and India. It is mainly composed of cis-α-irone, followed by cis-γ-irone.

The difference between these two species is very simple: flowers are white for Iris florentina and blue for Iris pallida.

Aromatherapy :

Informations provided below are taken from reference works in aromatherapy. They are given for information purposes only and can not constitute medical information, nor engage the responsibility of ScenTree.

The iris is known for its mucolytic properties and is recommended for use in bronchitis, asthma, whooping cough and dermatitis.

Comments :