Extraction process :

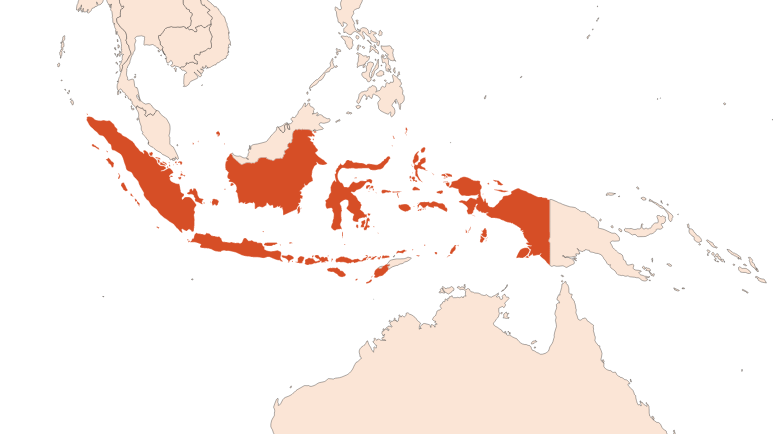

Plants are propagated by cutting because patchouli does not produce flowers and even fewer fruits. Plants are then arranged into rows, separated by a few tens of centimetres. The main harvest takes place during the wet season, from December to January, after 5 to 9 months of growth, early in the morning or late in the evening (this avoids the heat and thus the evaporation of the essential oil contained in the leaves). Leaves are picked one by one, without the stems. The subsequent harvests can take place every 3 to 6 months for 2 to 3 years. First cuts are generally more interesting from an olfactory and a yield point of view. Patchouli grows better at elevations of between 200 – 300 metres above sea level. Initially patchouli was grown in Sulawesi at sea level but growing at higher elevations improved patchouli quality with a higher PA and lower acidic value.

In order to get the most oil from the leaves, they are dried in the shade for about 1 week, turned over and then stored in a dry place (this increases the permeability of the leaves and allows to release a large part of the essential oil contained in the leaf itself). This step induces a loss of about 80 to 85% of the initial weight of the leaf. Similarly, the longer the drying process, the higher the quality of the essential oil. However, this waiting time reduces the yield.

After drying, leaves are ready to be extracted by steam distillation under pressure for 6 to 24 hours. Again, several types of distillation can take place. Differences mainly regarding the nature of the extraction tank. Indeed, in the poorest regions (Sumatra for example) tanks are made of iron and the volumes treated are very small. Iron is not optimal for patchouli because it is then found in the essential oil (Phenols contained in the EO react and form ferrous ions) and brings nothing more than instability (coloration). Products extracted by this way (approximately 10-20% of the world production) must then undergo a process known as ''de-ironation '' (treatment with citric acid, for example) in order to recover an interesting quality. This is known as ''Patchouli de-ironed ''. For several years now, producers, supported by the perfume industry, have been able to develop their production techniques and are now able to distillate more than 80% of the world's production in stainless steel vats capable of holding almost 10x the volume. These innovations have made it possible to gradually eliminate the iron removal stage. This is known as ''Patchouli light ''.

Regardless of the distillation method used, the yield between the dry leaves and the essential oil is below 2%.

Once distillation has been carried out, the EO undergoes a maturation stage of a few days in order to evaporate the first top notes considered as unpleasant (sulfuric notes).

It should also be noted that it is possible to obtain ''Patchouli Heart '' after fractional distillation. In the latter, only the central fraction of the essential oil is kept. Top and bottom fractions are removed. It is also possible to obtain ''Patchouli DM '' by molecular distillation. Finally, an extraction with volatile solvents is also possible, making it possible to obtain Patchouli Absolute. This process is however very rarely carried out because it is generally not appreciated by perfumers.

Chemotypes :

The genus Pogostemon is composed by 35 species. The patchouli used in perfumery is Pogostemon cablin. There is however a ''false patchouli '', the Pogostemon heyneanus. This patchouli is also grown in Indonesia and is often marketed as ''Java Patchouli '' or ''Sumatra Patchouli ''. Unlike Pogostemon cablin, it blooms and its essential oil has a lower quality.

Aromatherapy :

Informations provided below are taken from reference works in aromatherapy. They are given for information purposes only and can not constitute medical information, nor engage the responsibility of ScenTree.

Patchouli is renowned for its phlebotonic virtues (tones venous walls). It is indicated in case of acne and especially varicose veins.

Comments :